Better data = Smarter solutions

At McAlpine Hussmann, we understand the importance of reliable and efficient refrigeration and HVAC systems for businesses of all sizes.

That’s why we’ve developed CaseConnect™, our new Plug & Play innovative technology that integrates 8 IoT sensors into refrigerated cases and advanced cloud technology for energy savings, proactive maintenance, compliance and retail customer engagement. It’s data is open-source to import or integrate into your existing platforms or systems.

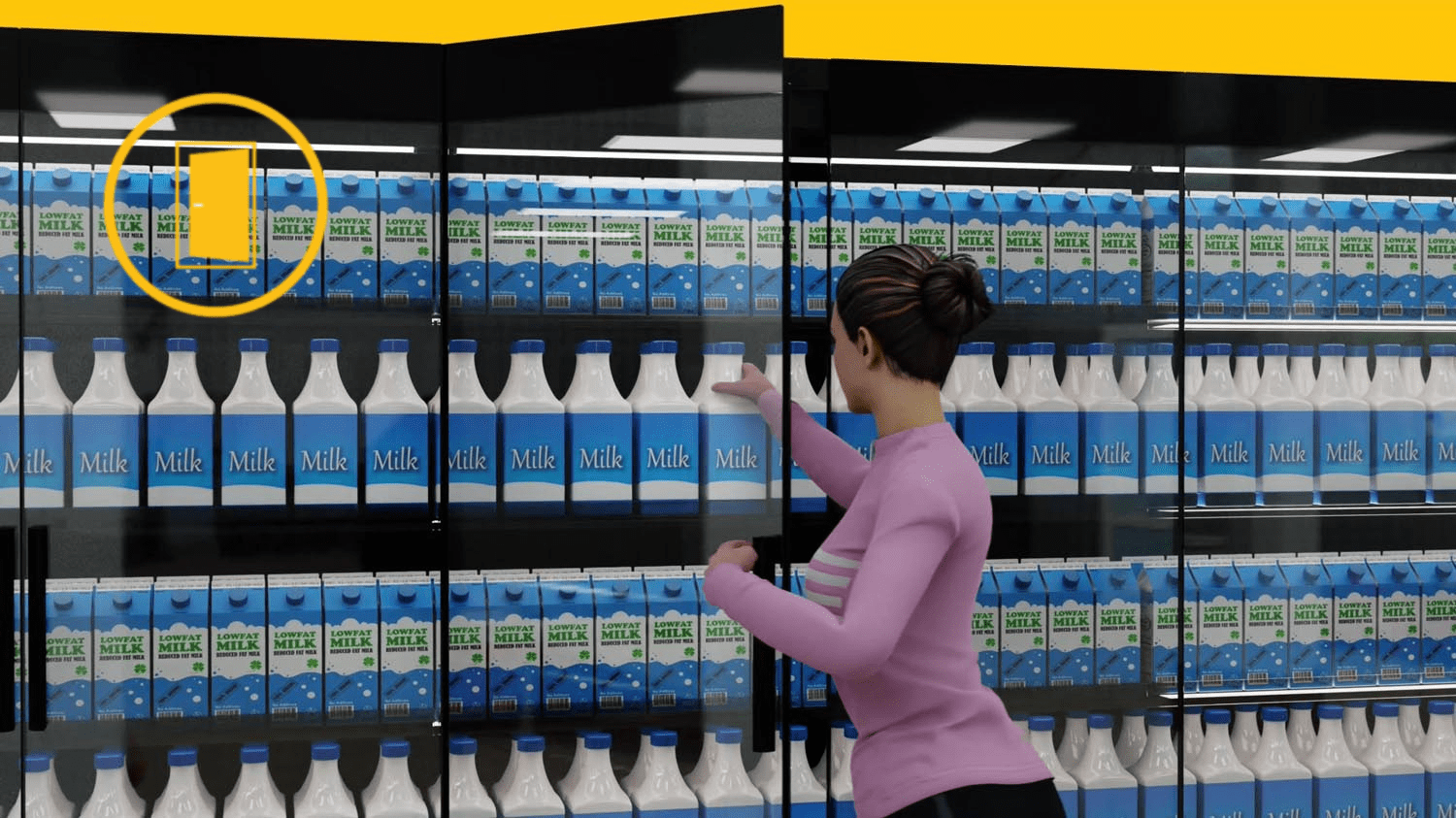

CaseConnect™ combines sustainability and increased ROI using innovative actions and real-time data on the product, customer flow and planogram engagement. With CaseConnect, you can manage all your assets from one central location, track service history, schedule maintenance, and receive real-time alerts for critical events. In addition, CaseConnect™ can be pre-fitted or retrofitted to any refrigerated display cases.

This innovation converts your refrigerated cases or refrigerated merchandises into intelligent self-monitoring, self-diagnosis appliances that align and optimise based on demand and seasonality while ensuring uncompromising food quality. Some key focus of our technology is to reduce energy, operational and maintenance costs. We have also built smarts to detect customer traffic to provide meaningful insights.

McAlpine Hussmann, are committed to providing our customers with innovative and user-friendly solutions to optimize their operations. With CaseConnect, you can enjoy peace of mind knowing that your refrigeration and HVAC systems are operating at their best while minimising downtime and expenses.

Get in touch today to learn more about our CaseConnect™ solutions.

CaseConnect™ – IoT Sensor Range

1. Doors IoT

Saving you Energy & Costs

- Door Open Alarm

- Plannogram Success Measure

2. Night Blind IoT

Saving you 14% of Energy Costs

- NB Open Alarm

- Fan Motor Energy Reductions

3. Blocked Air IoT

Increases Case Efficiency

- Return Air Block Alarm

- Optimise Performance

4. Blocked Drain IoT

Avoids Asset Downtime

- Automatic Drain Blockage Detection

- Avoids poor Hygiene & Customer Impact

5. Motor Service IoT

Focused Maintenance & Running

- Maximise Equipment Uptime

- Avoid Unsafe Product Temp

6. Demand Defrost IoT

Energy Savings and No Adjustments for Seasonality/Demand

- Avoids unnecessary defrosts

- Automatic Ice Detection

7. Product Temperature IoT

Saving you Energy & Costs

- Monitor Case Temp in Real Time

- Prevent Product Wastage

8. People Counter IoT

Customer Metrics

- Insights of High Flow Areas

- Plannogram Success Measure